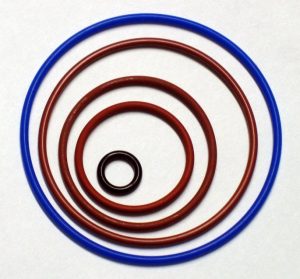

Almost every mechanical device requires some kind of o-ring. The o-ring is so common that we almost forget it’s there until there is a mechanical failure. A crack or break in an o-ring can create delays in production, expensive leaks or equipment breakdown. Preventing cracking in o-rings and finding knowledgeable o ring suppliers is essential in keeping machinery up and running.

Almost every mechanical device requires some kind of o-ring. The o-ring is so common that we almost forget it’s there until there is a mechanical failure. A crack or break in an o-ring can create delays in production, expensive leaks or equipment breakdown. Preventing cracking in o-rings and finding knowledgeable o ring suppliers is essential in keeping machinery up and running.

Why do o-rings crack?

The most common causes of o-ring failure are:

- Irregular compression

- Inadequate lubrication

- Using the incorrect size

- Incorrect installation

- Not storing o-rings properly

Since a defective o-ring can bring business to a crashing halt, maintaining and having replacements available is important.

Irregular compression can be caused by several mechanical issues, but typically is caused when a constant seal can’t be maintained. Without seal integrity, the o-ring can become deformed and break. Maintaining equipment can help prevent the loss of the seal integrity and also extend the life of your equipment.

Proper lubrication is important in prolonging the life of the o-ring, but also in maintaining a constant seal. The type of o-ring and the type of equipment used determines the kind of lubricant required. Using the wrong lubricant or not enough lubricant can shorten the life of the o-ring but also cause irreparable damage to equipment. Before applying lubricant you should consult with a trusted o-ring supplier.

Using the incorrect size o-ring will cause it to quickly crack or break under pressure. Incorrectly sized o-rings may cause parts to slip or make contact with other parts that should be separated by the o-ring. This can also prevent seal integrity, leading to equipment failures and expensive repairs.

O-rings can also be installed incorrectly. Correctly installing an o-ring involves using the proper lubricant, placement, and size. There are different o-ring installation tools depending on the type of o-ring the equipment requires. The installation tools may be provided with the equipment or may need to be purchased separately

Lastly, o-rings should be stored away from ultraviolet or fluorescent light or direct sunlight to prevent cracking before they can be installed. O-rings should not be stored while stretched. Stretching o-rings before installation should only be done if instructed by the manufacturer.

O Ring Suppliers and Manufacturer You Can Count On

Do you still have questions or need a simple guide to selecting an o ring? Contact Manufacturer’s Rubber and Supply. We are your source of information and the o-ring supplier you can count on to exceed all of your expectations.