Manufacturer’s Rubber & Supply offers a wide selection of high-quality gaskets guaranteed to meet the most challenging application requirements. The mechanical seals form pressure-tight seams between two or more mated surfaces. They are instrumental components found in every mechanical, hydraulic, electrical, or pneumatic machine, tool, mechanism, motor, pump, engine, or like device used in industrial production, manufacturing, and commercial environment.

In addition to preventing the emission or contamination by absorption of unwanted fluids, lubricants, or gases within a mechanical assembly, applications for gaskets vary widely. Gaskets are also used for cushioning, packaging, dampening, hygiene, noise reduction, and sound attenuation, weather resistance, anti-vibration, insulation, and other applications.

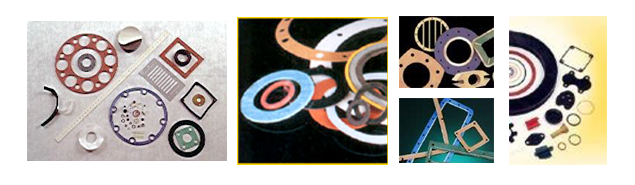

Our gaskets come in numerous shapes, sizes, materials, and designs—die formed, spiral wound, die-cut, lathe cut, molded, machined, extruded, encapsulated strips, EMI/RFI shielding, jacketed and double-jacketed, grooved or Kammprofile, and even hand-cut.

When selecting gaskets for your application keep in mind that gasket materials are chosen for their mechanical properties, characteristics, and capabilities designed for the application. Many are made of cork, felt, metal, fish paper, foam, and composites. Most are made of synthetic rubbers—EPGM, Neoprene, Silicone, Teflon®, Viton®, PTFE, Nitrile, or Urethane—that consist of various elastomeric compounds dependent on the application requirements of the gasket.

Composition of rubber materials varies relating on their function. Some are designed for contact with corrosive substances, fluids, or chemicals, while others are designed for oils and lubricants. Petroleum-based fuels, for example, require different gasket material than that used in food processing environments. The strength of some types of synthetic rubbers wears down prematurely when used in electrical applications, while the wrong component material in oxygen-related applications can lead to fatigue cracks and brittleness. Silicone-based gasket material is ideal for use in extreme temperature applications while gaskets such as Nitrile, Viton®, and Neoprene can go through a high degree of deformation while under pressure without loss of attributes or permanent damage to the material.

For more information, contact Manufacturer’s Rubber & Supply to discuss your gasket requirements.

Gaskets: All Shapes and Sizes | Custom Gasket Manufacturer: Die cut, Lathe cut, Hand-cut, Machined, EMI/RFI shielding, Molded, Extruded, Die-formed, Spiral wound, and Encapsulated strips.

Types: Flange gaskets (full face and ring), Pump gaskets, cover gaskets, gasket kits, Diaphragms, Manhole and Handhole, Spiral wound gaskets, insulator gaskets, jacketed gaskets, non-metallic, Teflon® envelope gaskets, and die formed.

Materials:

EPDM Gaskets

Non-asbestos Gaskets

PTFE Gaskets

Cork Gaskets

Neoprene Gaskets

Felt Gaskets

Vegetable Fiber Gaskets

Teflon® Gaskets

Aflas Gaskets

Nitrile Gaskets

Silicone Gaskets

Urethane Gaskets

Closed and Open Cell Sponge Gaskets

Cloth Inserted Gaskets

Pure Gum Gaskets

Vellumoid Gaskets

Fish Paper Gaskets

Grafoil Gaskets

Red Rubber Gaskets

Rubber Gaskets

Viton® Gaskets

Rubber & Gasket Fabrication:

Die cut gaskets

Hand cut gaskets

All shapes and sizes

All materials stripped to any width

Pressure sensitive adhesive for all materials

48 hour die service